Our coils are used in heating equipment, ventilation equipment, and cooling or air-conditioning equipment used in domestic, commercial and industrial HVAC systems to control the temperature, humidity, and purity of the air.

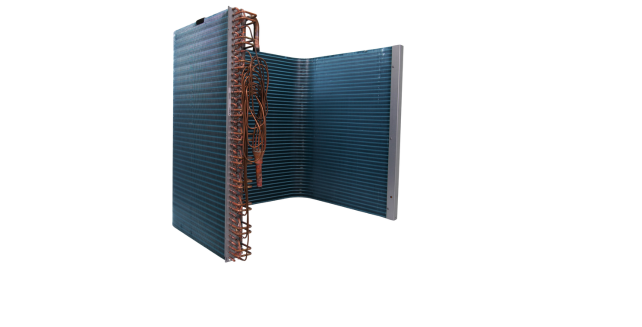

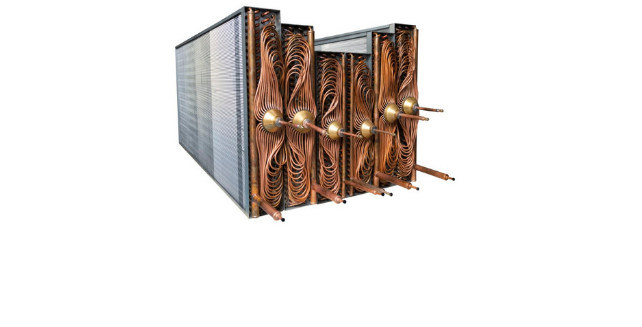

We offer fin-and-tube type heat exchanger coils with different patterns of heat exchanging surface depending on disposition of the tubes in height and in rows and depending on diameter of tubes. Copper tubes we use can be smooth or grooved with external diameters: 5 mm, 7 mm, 9.52 mm, 12.7 mm, 15.88 mm.

We use aluminum and copper fins with plain, waved or louvered surface and with different fin thickness. Fin space, on which the performance of the condenser depends, can vary from 1.15 till 8.47 mm (3-22 FPI). Fin material used can come with different types of anti-corrosion coating and is selected based on the area of application. The customer can choose a desired color for painting our heat exchangers.

To ensure the highest quality results, we manufacture headers and end plates in our own press shop. Each coil is tested for leaks with high pressure air in water bath or with helium in helium testing chamber. We pack the coils in strong packaging adapted to transport the goods around the world by sea, land and air.

We have the capability to manufacture a wide range of standard as well as customized coils in any dimension and capacity to match customers’ technical specifications in terms of quality and performance. All technical parameters of our coils we can check with a program UNILAB.

Our fin-and-tube type coils are made of the highest quality raw materials.

Our raw materials (copper tubes and metal sheets) and semi-finished & finished products (aluminum fins, copper headers and fittings, end plates, evaporator coils) are tested under our Standard Operating Process (SOP) at all the key stages of production.

Our design, production and testing team use their expertise to match the technical specifications set by our customers in terms of material, design, quality and performance. Our coils meet the required international products and quality standards like UL certifications.

We have a wide range of products, and we are also capable of manufacturing customized the coils in any dimension and capacity for our client’s specific need. And YES! We do this for you within the defined timeline and quality parameters!