Discover what we can do for you—Download our brochure now!

0

Manufacturing

Facilities

0

Satisfied

Customer

0

R&D

Facility

0

Skilled

Workforce

Welcome to KRN Heat Exchanger and Refrigeration Limited

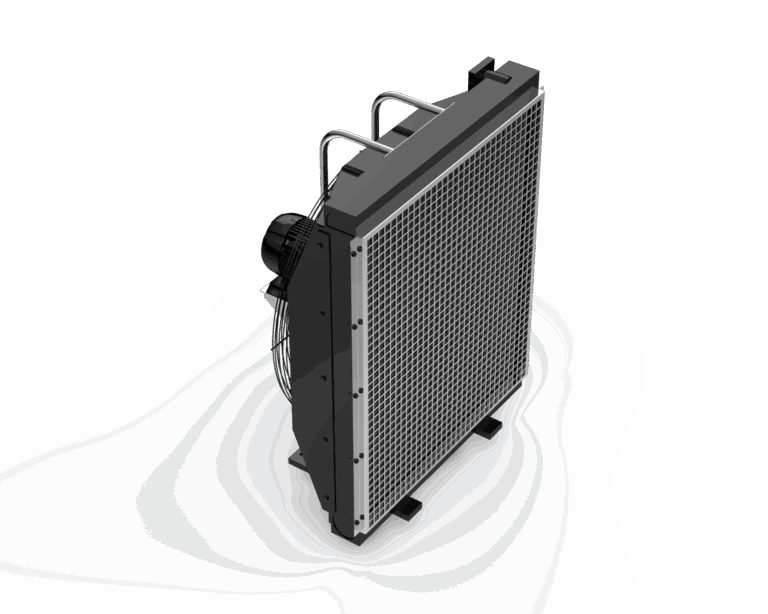

KRN Heat Exchanger & Refrigeration Ltd. is a leading manufacturer of heat exchangers, cooling coils, and advanced HVAC & refrigeration solutions, headquartered in Neemrana, Rajasthan, India. With modern manufacturing facilities, skilled teams, and a focus on engineering innovation, KRN delivers products that meet the evolving demands of HVAC, refrigeration, automotive, power, marine, food processing, and industrial sectors.

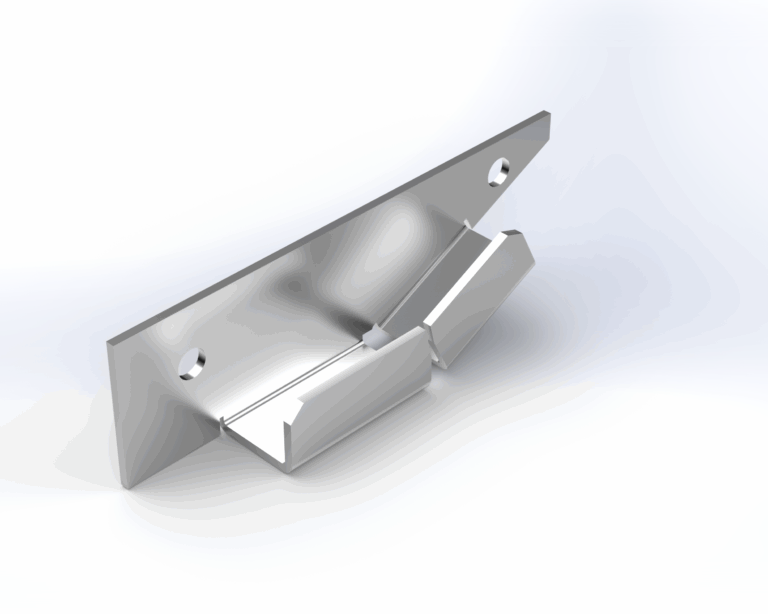

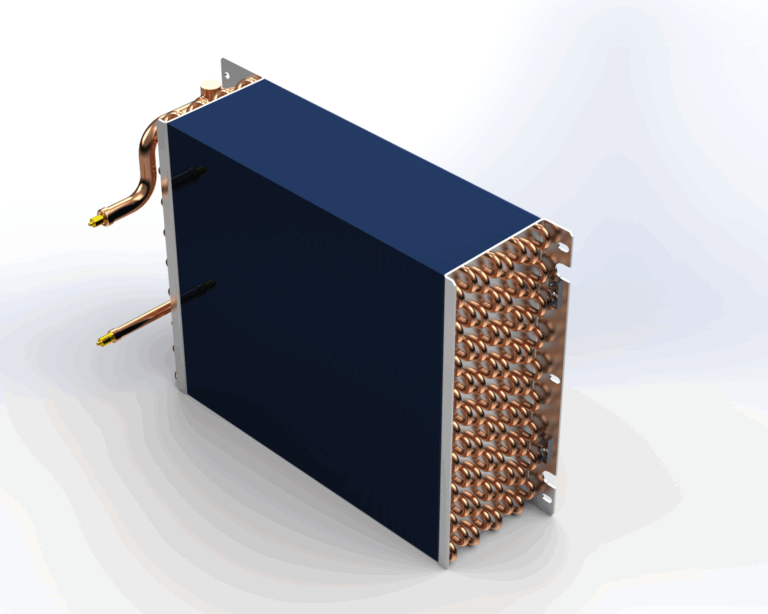

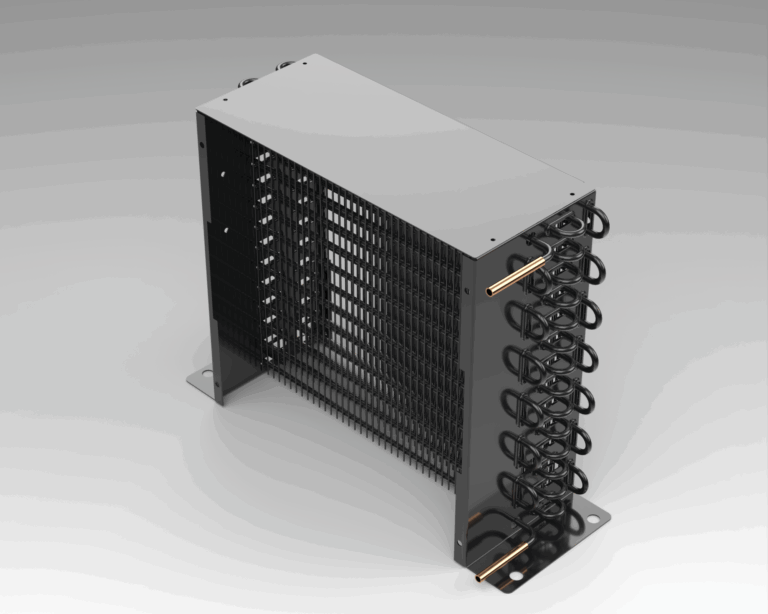

Our comprehensive product portfolio includes Fin & Tube Coils, Bar & Plate Heat Exchangers, Refrigeration Components, Complete HVAC Systems, Micro Channel Heat Exchangers, Technical Tubes, Sheet Metal Components, and Tubings. Built with premium materials, precision technology, and strict quality standards, our products are designed for efficiency, durability, and global reliability.

With a strong emphasis on customization, testing, and international certifications, KRN has become a trusted partner for OEMs and global clients. Guided by our vision of delivering sustainable and high-performance thermal solutions, we continue to expand our footprint in India and worldwide.

KRN CERTIFICATIONS

We are a certified company with ISO 9001:2015 QMS (Quality Management System), ISO 14001:2015 EMS (Environmental Management System), and ISO 45001:2018 (Occupational Health and Safety Management System) certifications.

Our coils are certified with BIS (IS 11329:2018), UL-207 recognition and CE (Pressure Equipment Directive 2014/68/EU) standards. They also adhere to RoHS guidelines under Directive (EU) 2015/863 & Directive 2011/65/EU and meet the requirements of REACH regulations. As a result, our products are used by OEM clients without the need for re-qualification. Moreover, our brazing process has been approved with BS EN ISO 13134, and it is carried out by our certified technicians as per BS EN ISO 13585.

OUR VALUABLE CLIENTS

Online Resolution of Disputes in the Indian Securities Market

Securities and Exchange Board of India (“SEBI”) vide its Circular No. SEBI/HO/OIAE_IAD-1/P/CIR/2023/131 dated July 31, 2023 as subsequently amended vide Circular No. SEBI/HO/OIAE_IAD-1/P/CIR/2023/135 dated August 4, 2023 (jointly referred hereinafter as “Circular”) has introduced a common Online Dispute Resolution Portal (“ODR Portal”). This platform is designed to enhance investor grievance redressal by enabling shareholder to access Online Dispute Resolution (ODR) for the resolution of their complaints.

A common ODR Portal, called the SMART ODR has been established for this purpose, the link to access the portal: https://smartodr.in/login

Our Corporate Video

Our story, our passion, and our purpose—captured in one powerful video. Learn how KRN is making a difference in our industry and beyond.